HWS Victorian Rail Buffer Stop with Upright HO Scale (2pcs) HEARNS WORKSHOP

$ 14,99 $ 8,99

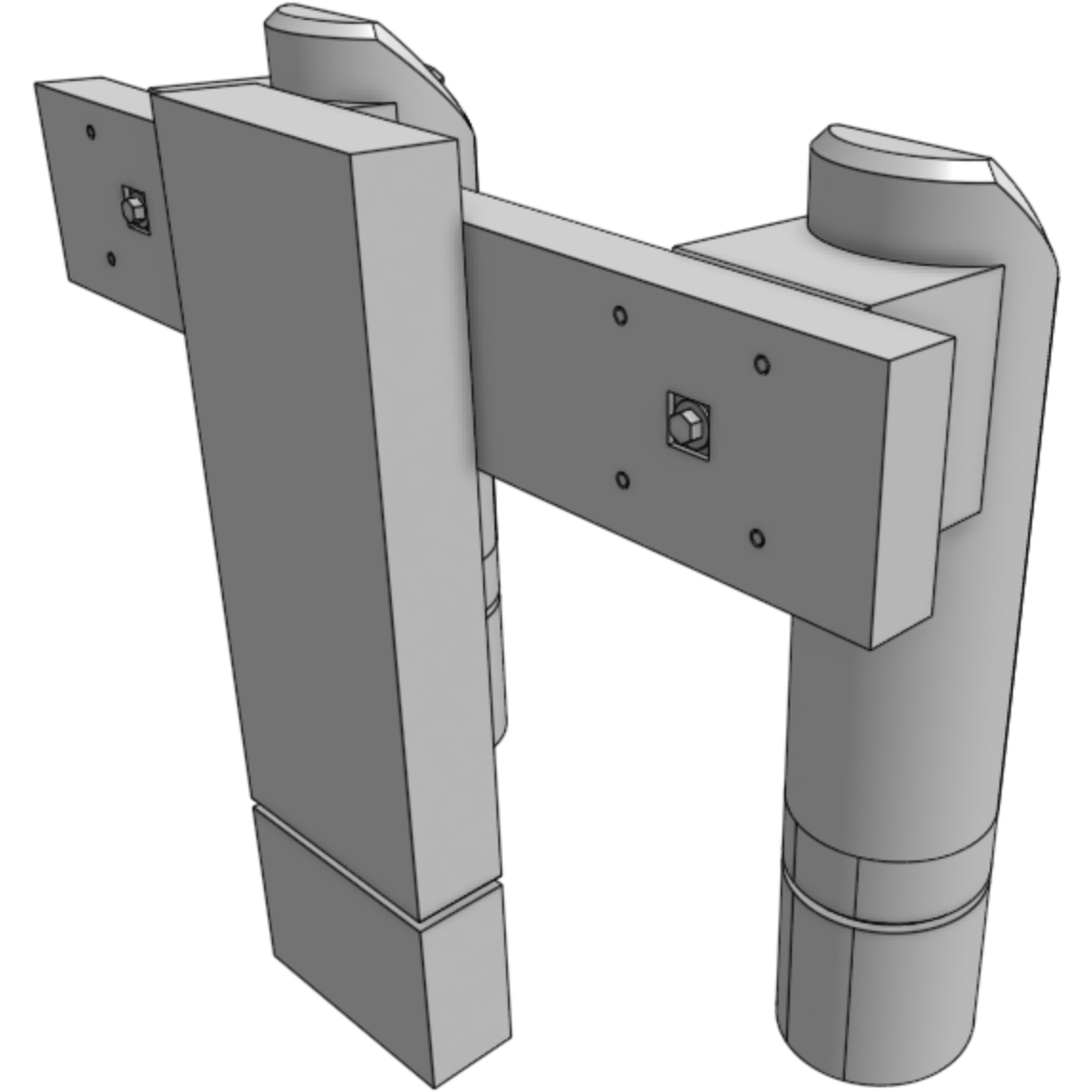

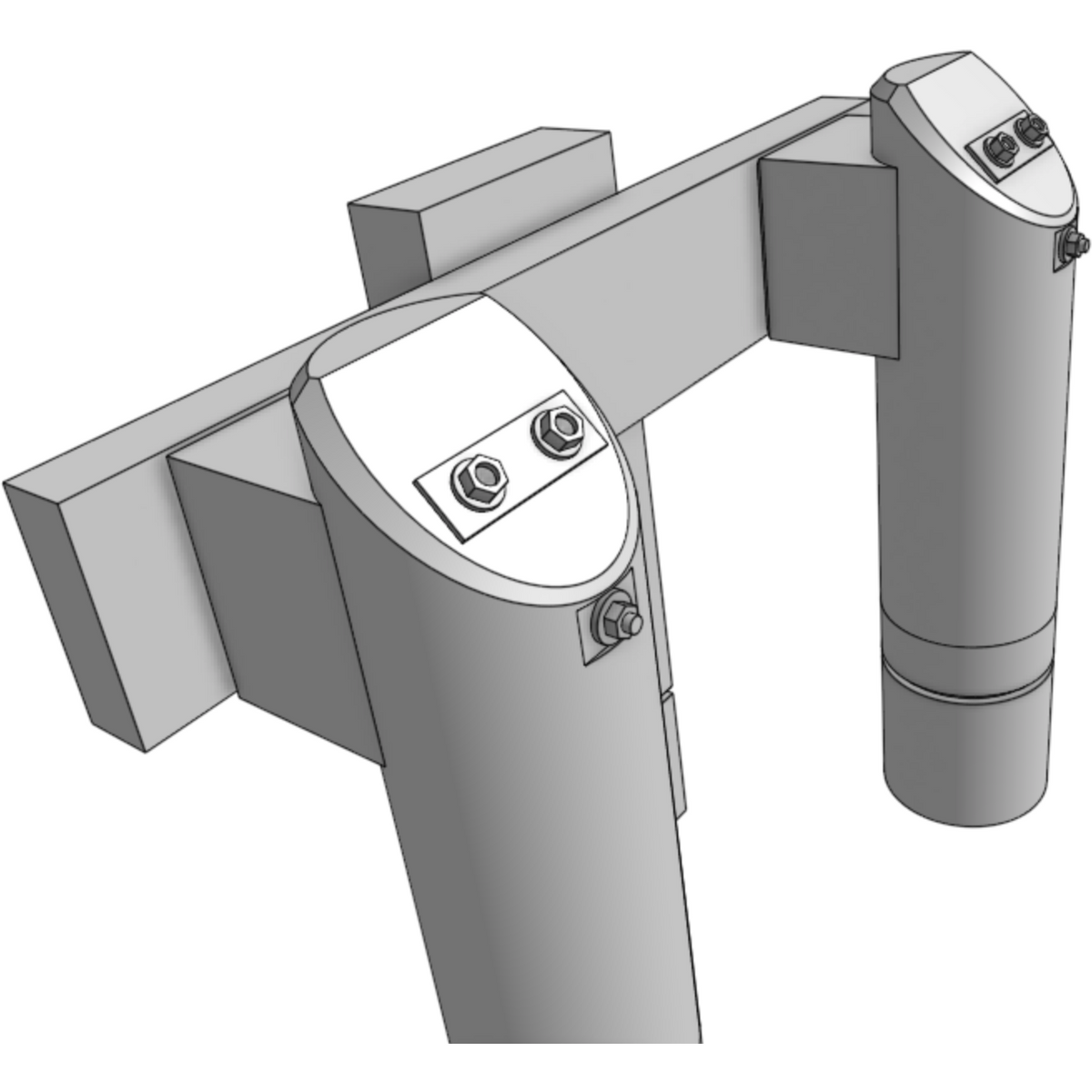

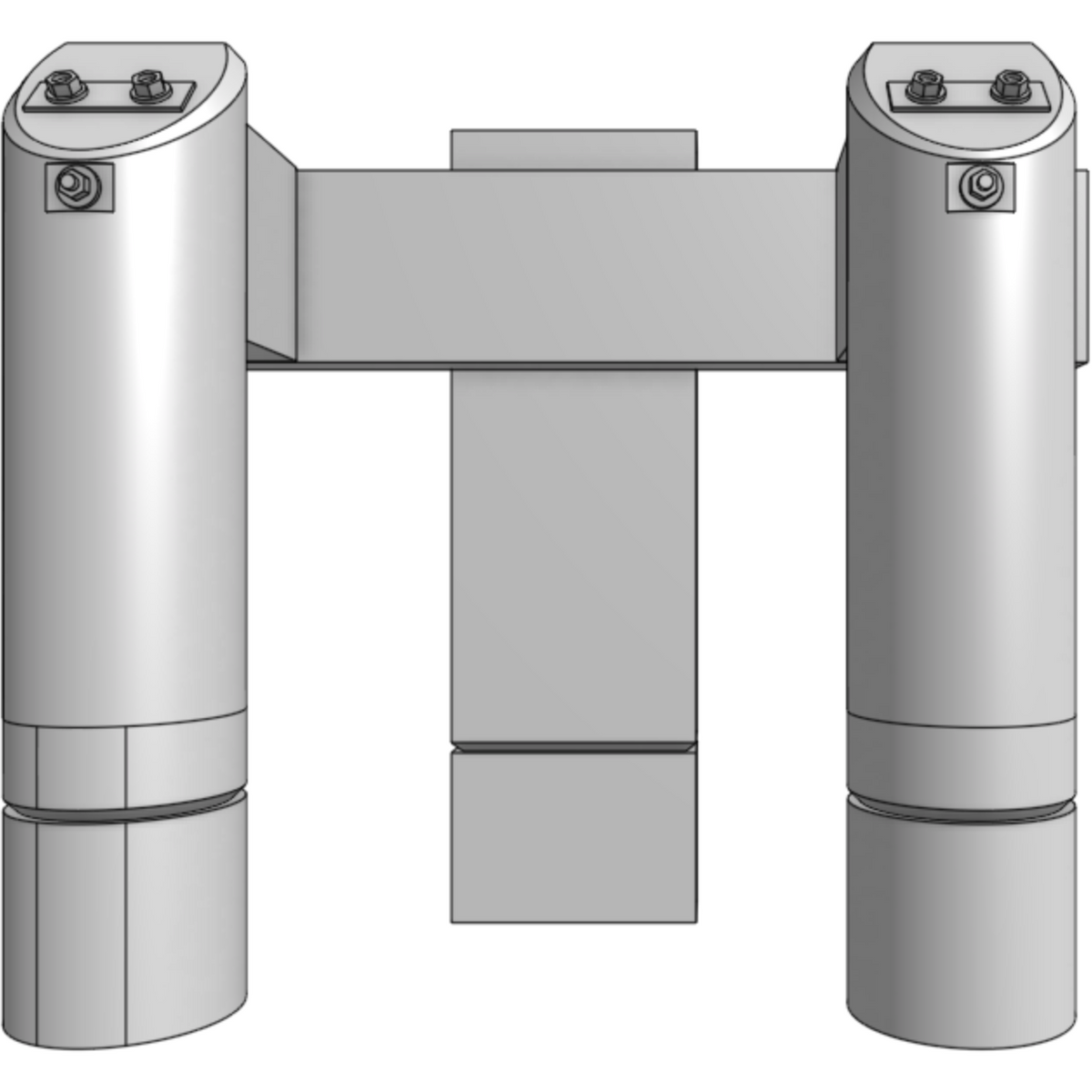

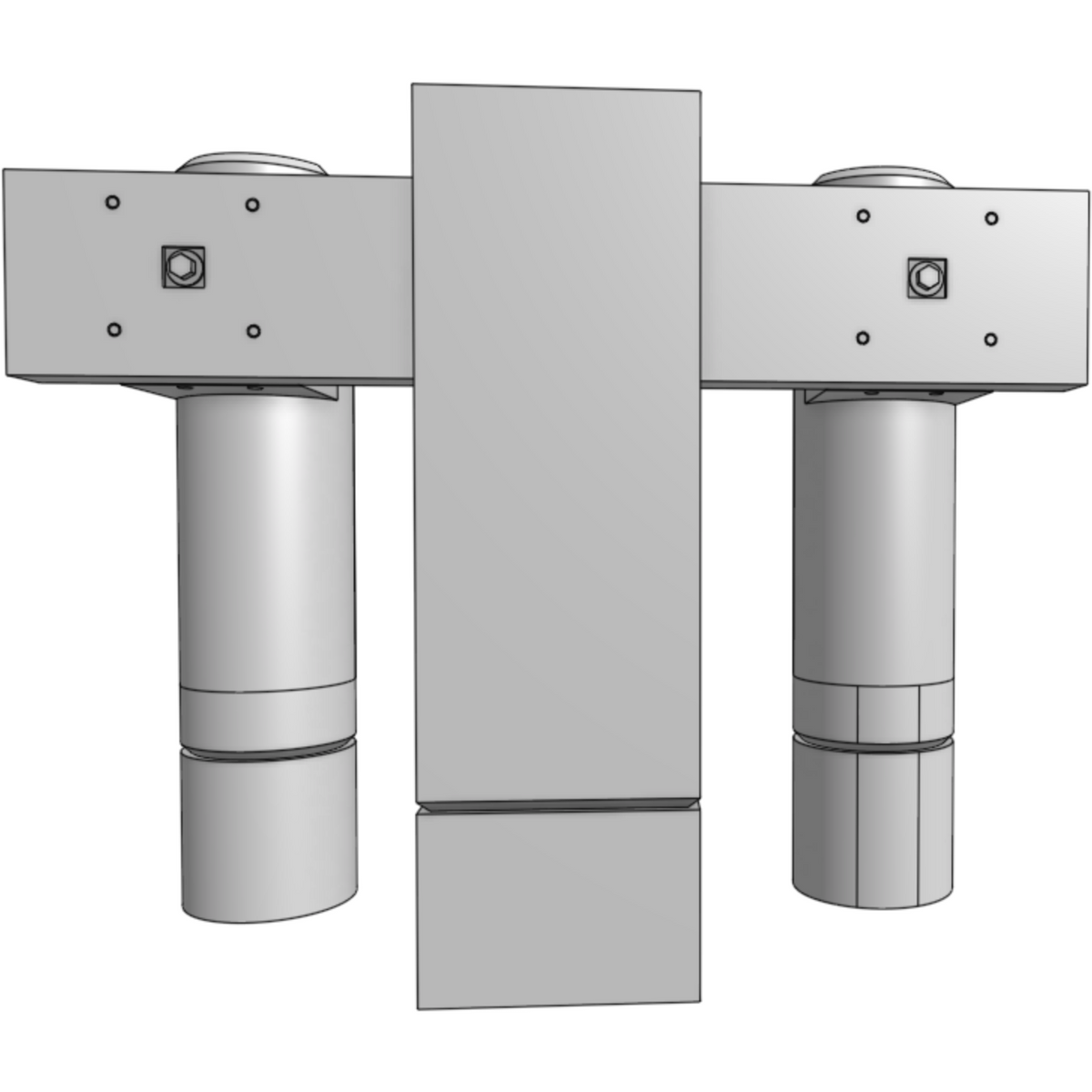

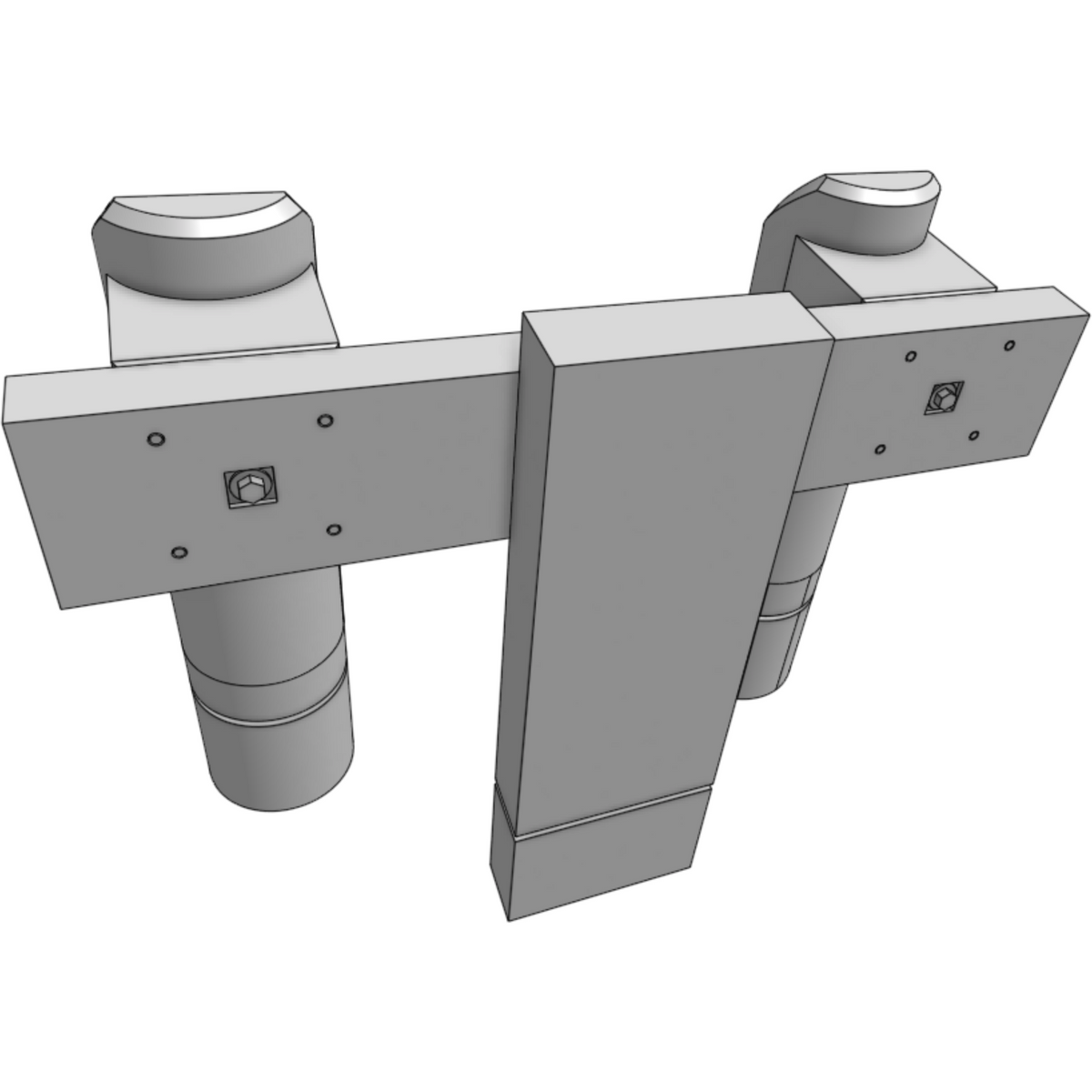

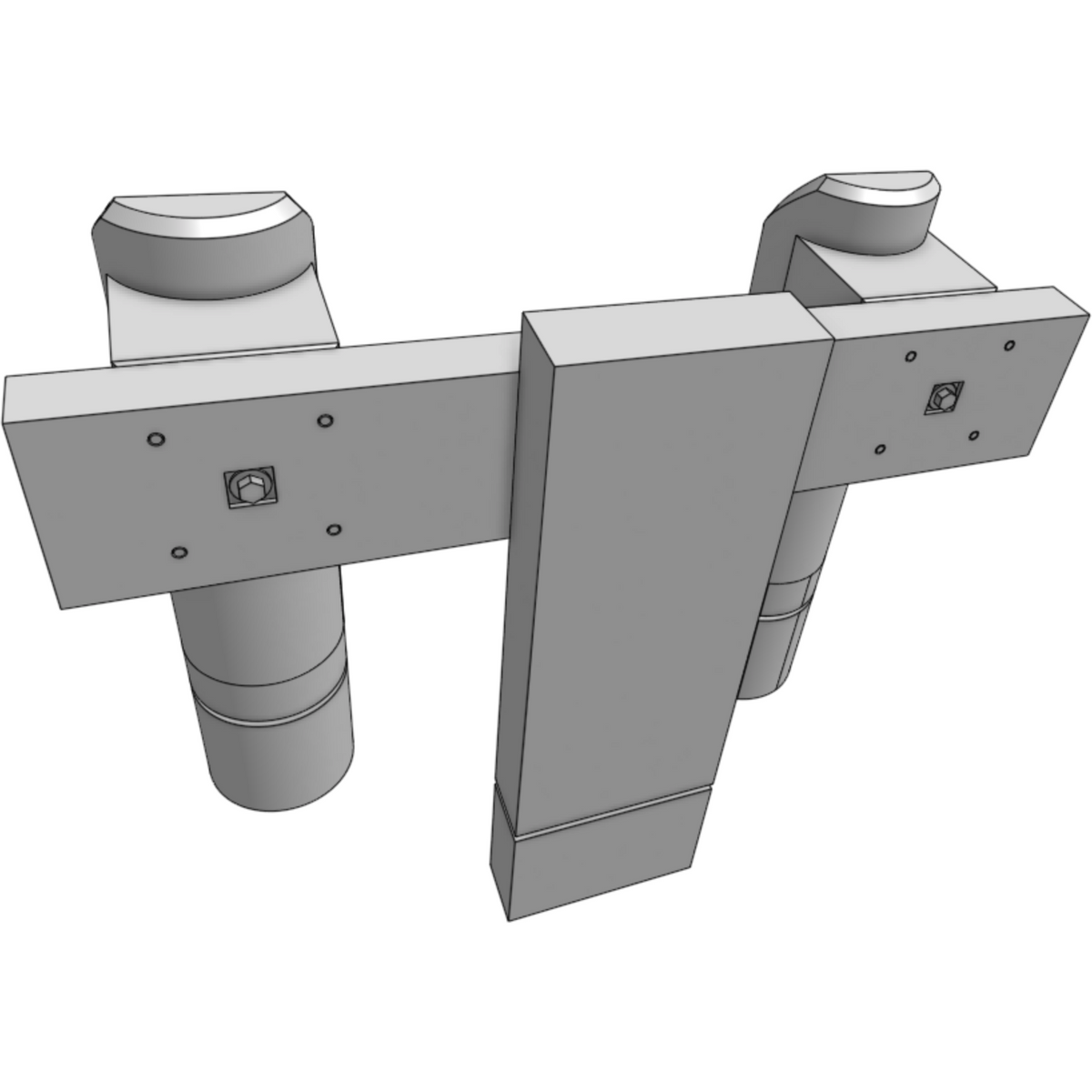

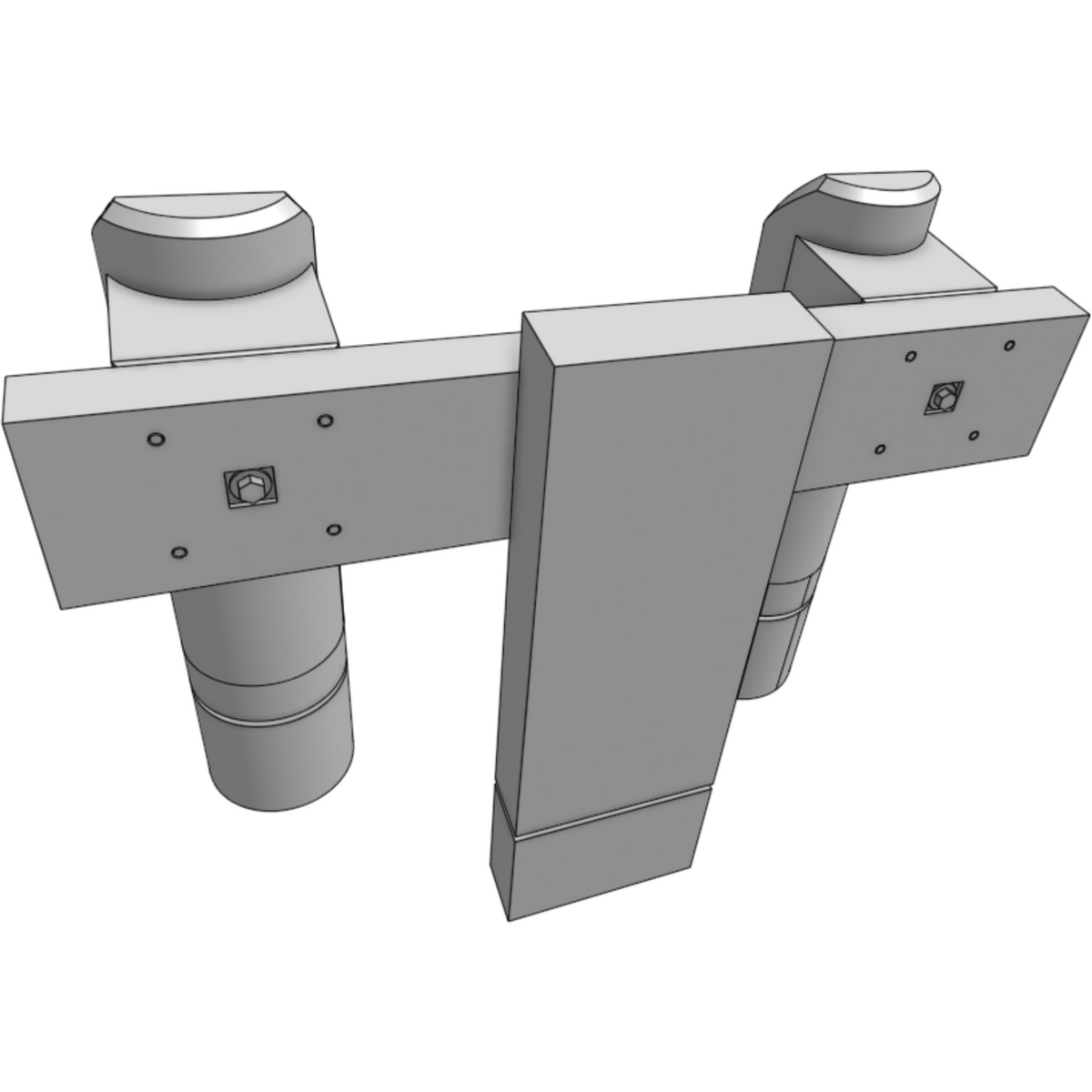

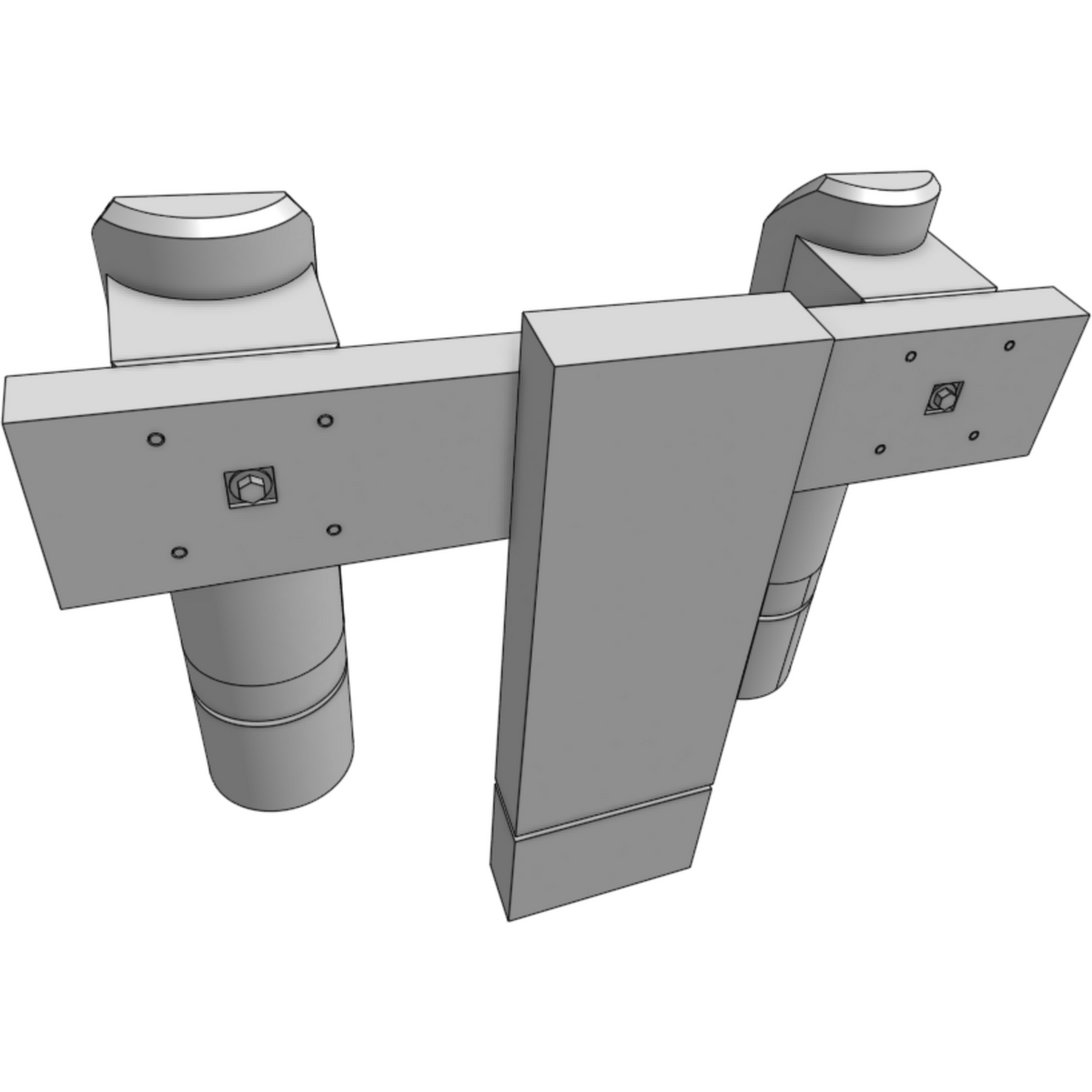

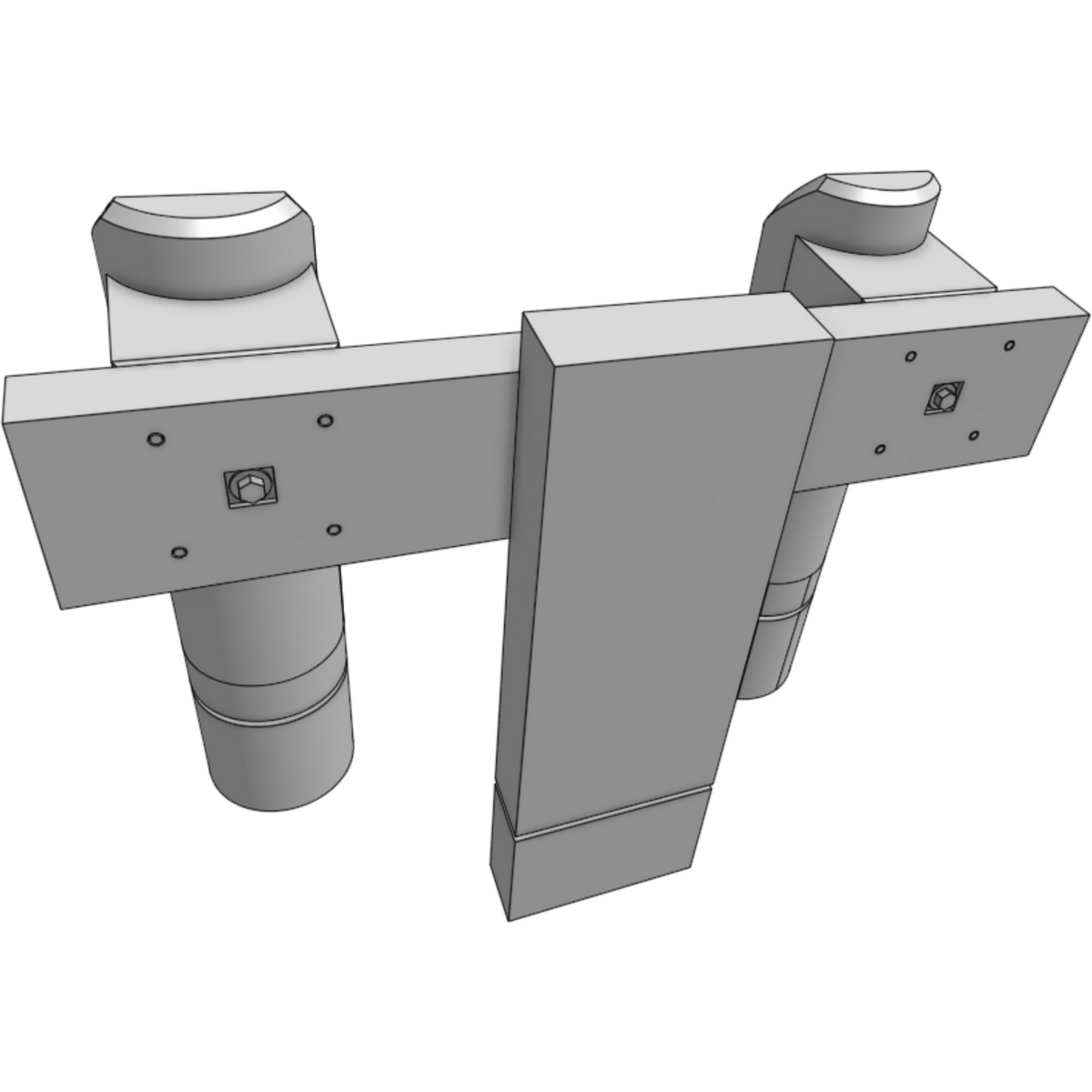

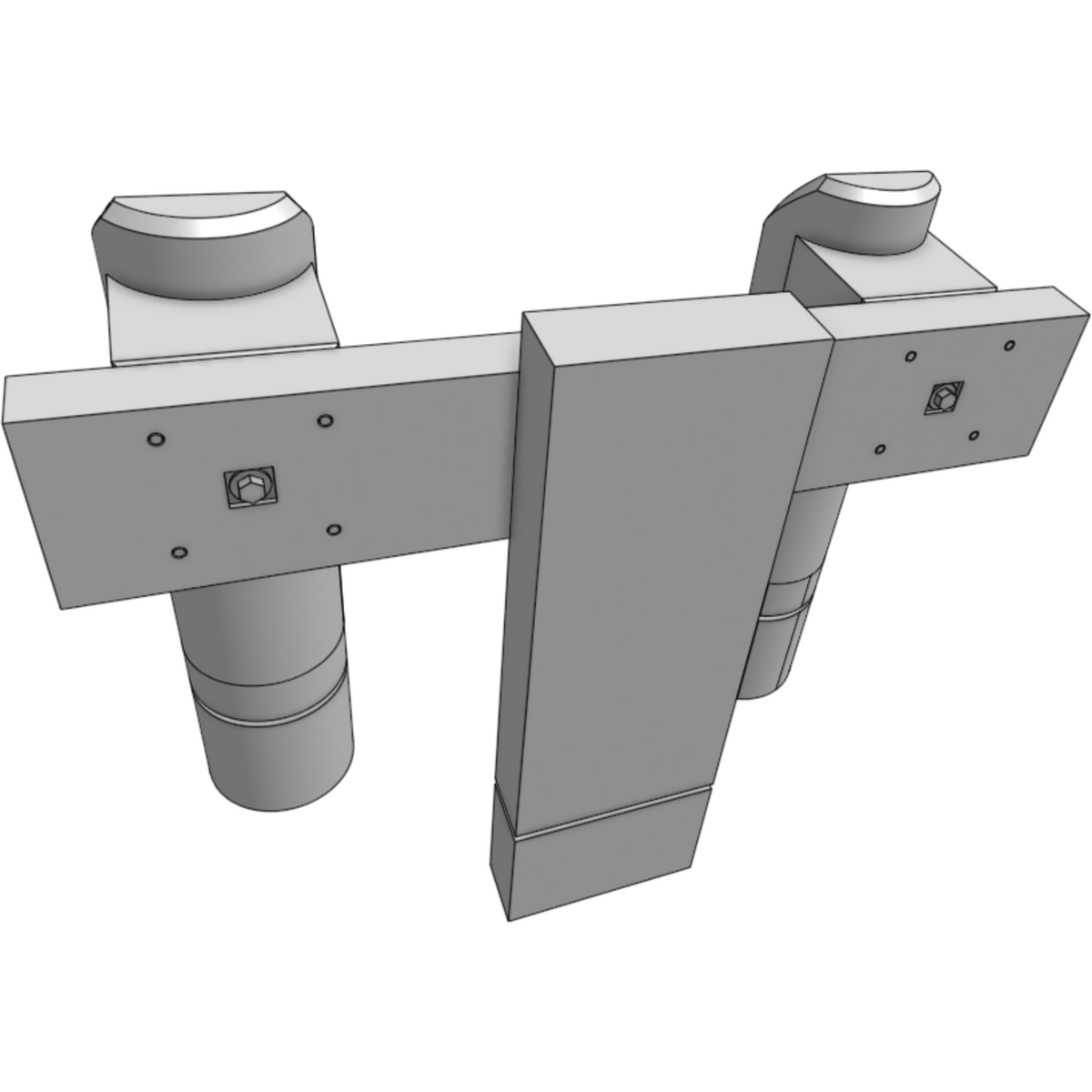

HWS VICTORIAN RAIL BUFFER STOPS WITH UPRIGHT HO SCALE (2pcs) (HWS0047-HO)

This kit is a representative of a Victorian Railways Buffer Stop as used on the Broad Gauge rail network all over the state of Victoria and would be found at the ends of significant rail sidings such as cattle yards or passenger car storage areas or in the end of a mainline into a station yard . This version has a middle vertical beam which was required once the VR removed buffers from there rollingstock and began using auto couplers. This kit can be used on a layout from the early 1940’s through to the present day .

Preparation:

Step 1: Remove the Buffer from the print supports (if required) with care and clean up with a fine sanding pad

Step 2: Locate the postion where the buffer is to be mounted in your scene and drill two 4mm holes

Step 3: Drill x4 holes with pin a vice using a 77′ drill bit under the Bulkhead. There is pre-marked holes. Cut x4 lengths of wire and lightly glue to bulk head with superglue. Trim to fit. .

Step 4: Undercoat and paint . Tamiya Surface primer gray ( fine ) is ideal . Once dry paint the whole the entire buffer flat white even the tie rods down to rail level .

Step 5: Glue the Buffer into the pre drilled holes with superglue or a small amount of epoxy glue and lightly glue the tie rods down to rail level .

Your Buffer is now in place and various groundcovers such as those from Woodland Scenics to represent weeds and grass as well as ballast add the finishing touches. These buffers have lasted into current day use and are usually heavily weatherd with little or no paint on them, returning back to a natural timber gray colour.

Happy Modelling!

DISCLAIMER Parts are manufactured from a UV curing resin. Cyanoacrylate (CA) or “Super Glue” recommended for bonding to rigid PS/ABS or other resin parts. UV curing resins can be an irritant. Always use the appropriate safety gear when handing or modifying. Parts are supplied still attached to the supports/raft. Care must be taken when removing supports. 3D printing IS NOT injection molding! Slight imperfections and the visible appearance of ‘layer lines’ in places is perfectly normal and not a defect. ‘Tough’ grade resin parts can damage fine bladed side cutters – use at own risk. For advanced modellers only.

Quick Shipping and Professional Packaging

Due to our long-term partnership in a long-standing partnership with UPS, FedEx, DHL and many other leading global carriers, we are able to offer an array of shipping options. Our warehouse staff are highly trained and will pack your products according to our precise and precise specifications. Your items will undergo a thorough inspection and be securely secured prior to being delivered. We ship to thousands clients each day across multiple countries. This is an indication of our dedication to being the biggest online retailer in the world. The warehouses are located in Europe as much as they are in the USA.

Note: Orders that include more than one item are assigned a processing time in accordance with the item.

Prior to shipment before shipping, we'll inspect thoroughly the items you've ordered. The majority of orders are shipped within 48 hrs. The time to deliver varies from 3-7 days.

Returns

We don't manage the stock in our warehouse and factory. Stocks are subject to change at any moment. You may not receive your order after the order has been made.

Our policy is for 30 days. If you have passed 30 days by since your purchase, unfortunately we can't offer you a refund or exchange.

The item cannot be used and in its original condition. It should also be in the original packaging.

Related products

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

(Clearance Item) HB RACING 44mm Heavy Duty Universal Drive Shaft/Rear/Steel/2Pcs HB RACING

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL