GODHAND SPN-120 Ultimate Nipper 5.0 GODHANDS

$ 97,99 $ 48,99

GODHAND SPN-120 ULTIMATE NIPPER 5.0 (GHSPN120)

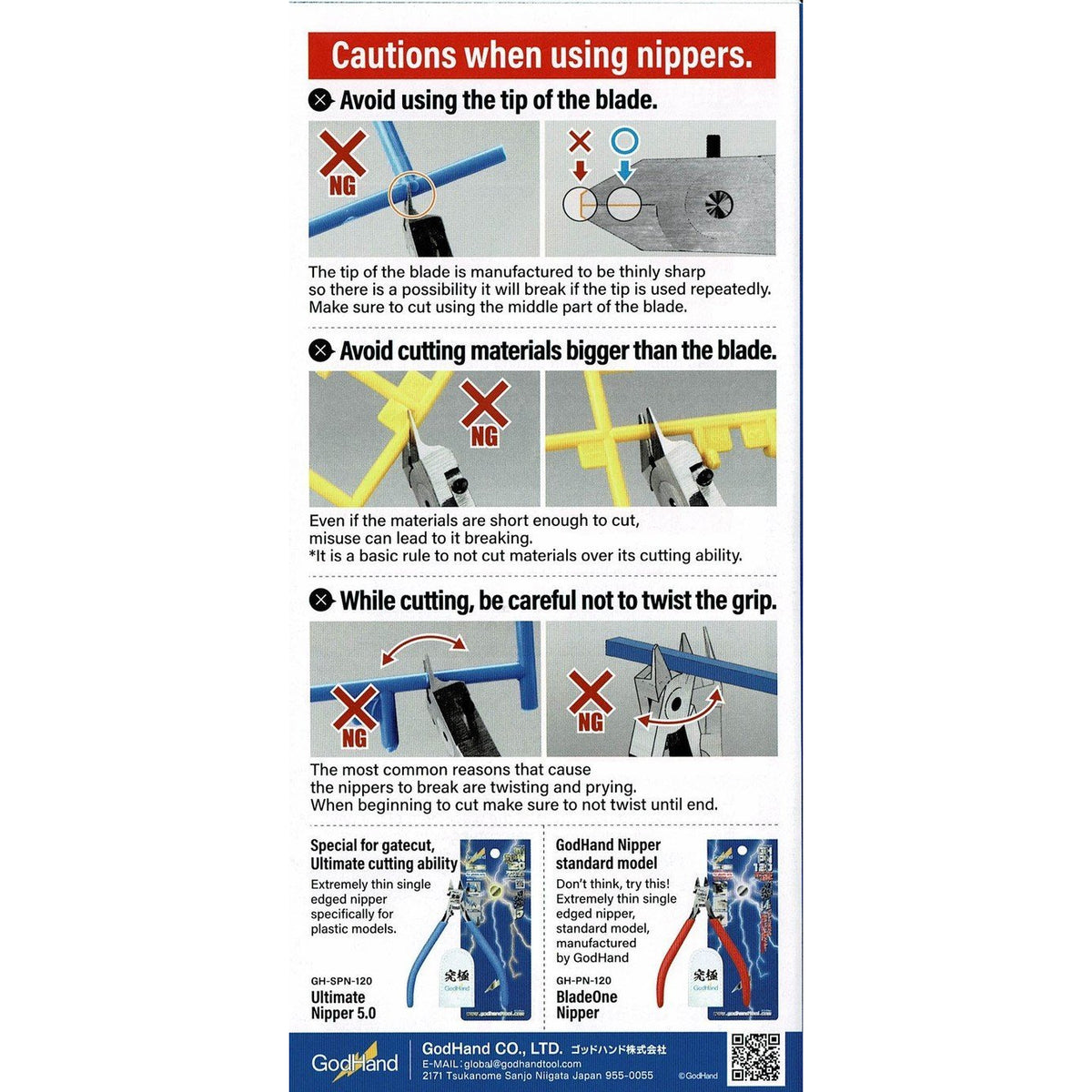

A legend within the international modelling community, the GodHand GH-SPN-120 focusses on achieving the most efficient, cleanest possible part removal from plastic kit sprues or runners. If you build a lot of kits, or you’re a modeller dealing with exhaustive numbers of tiny, easily damaged plastic parts, such as individual tank track links, you’ll truly appreciate the precision of cut and the smoothness of operation provided by the Ultimate Nipper. It is the benchmark against which all other plastic nippers are compared!

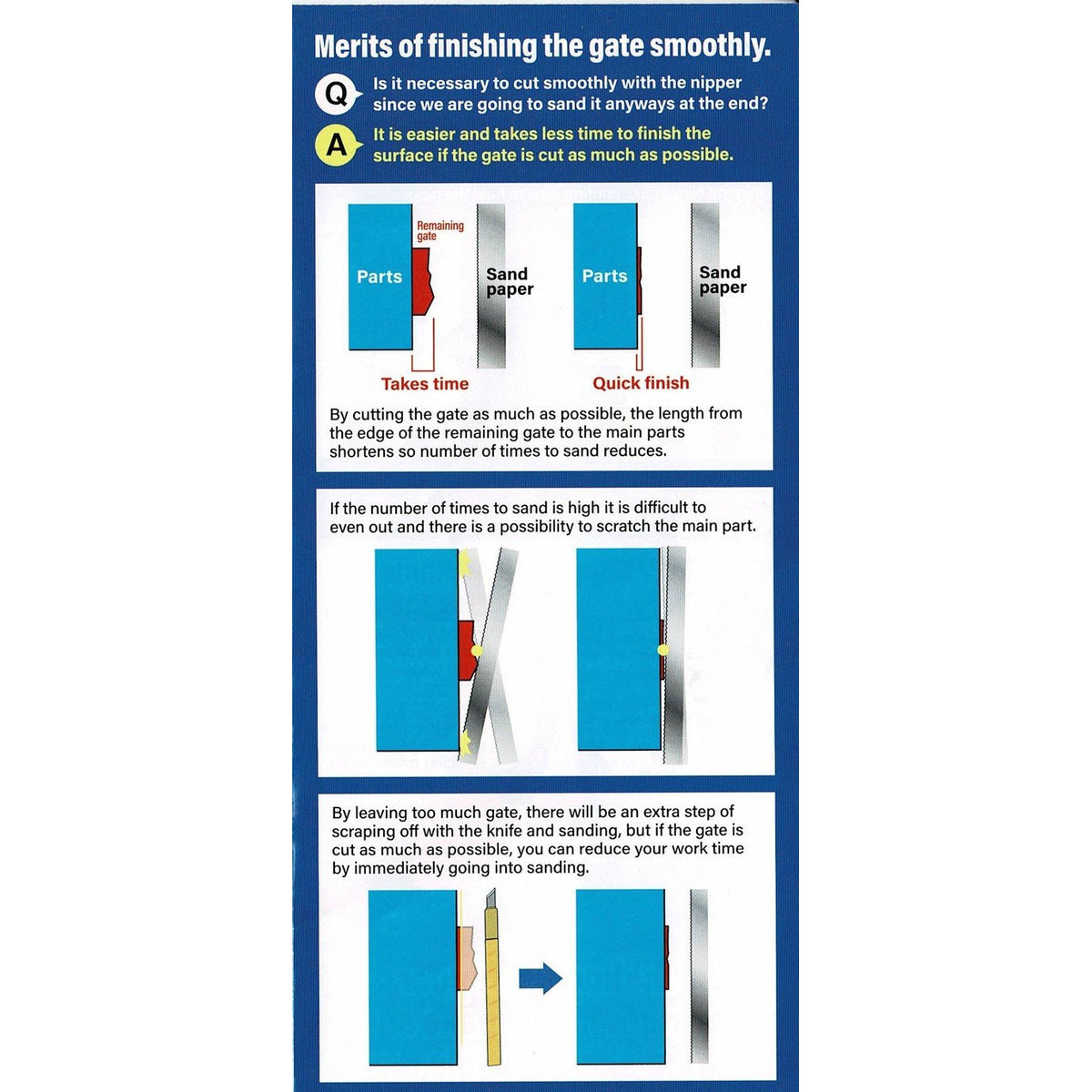

Due to the sharpness of the GH-SPN-120 cutting blade, you can obtain a smooth surface with little to no plastic whitening or gouging and with a minimum of scraping, sanding and polishing. This greatly improves kit construction efficiency, allowing you to speed through assembly steps without those often frustrating hours of sprue gate removal and clean up. The neat cut provided by the GH-SPN-120 Ultimate Nipper is also perfect for those whom do not wish to paint their model, a feature highly desirable to snap-fit model builders in particular.

Suitable for plastics only, these nippers can be used on PS, PP, ABS and PE resins to 3mm, with transparent/translucent PS resin being limited a maximum of 1mm.

Highlights:

* Arguably the most precise, smoothest plastic kit sprue gate cutter available.

* Material: Special tool steel (manufactured by Kobe Steel Works).

* Total length: Approx 120mm.

* Weight: Approx 60g.

* Blade hardness: HRC 58 or more.

* Single-edged specification.

* Soft grip.

* Original nipper cap included.

* Made in Japan.

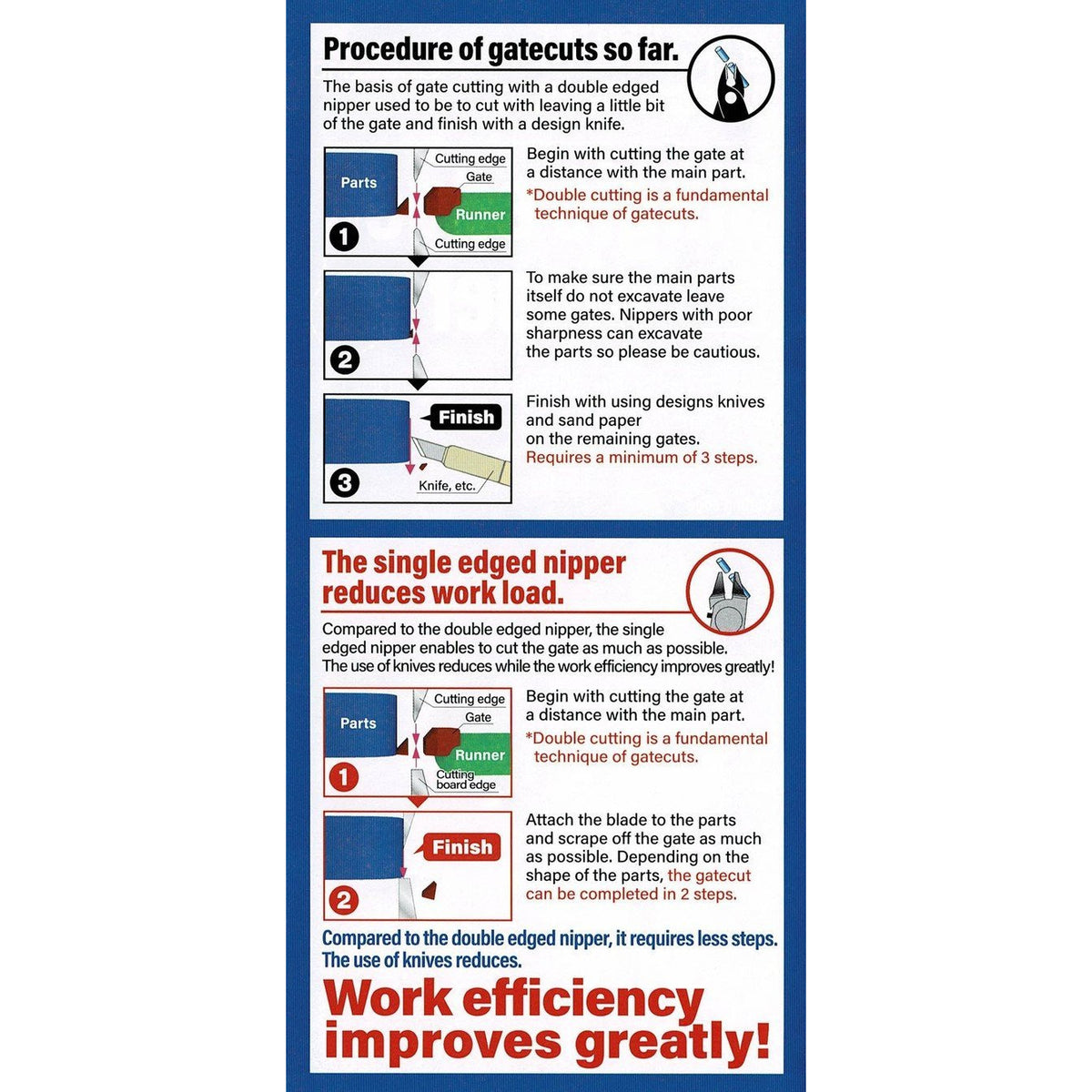

Double Edged v. Single Edged Nippers?

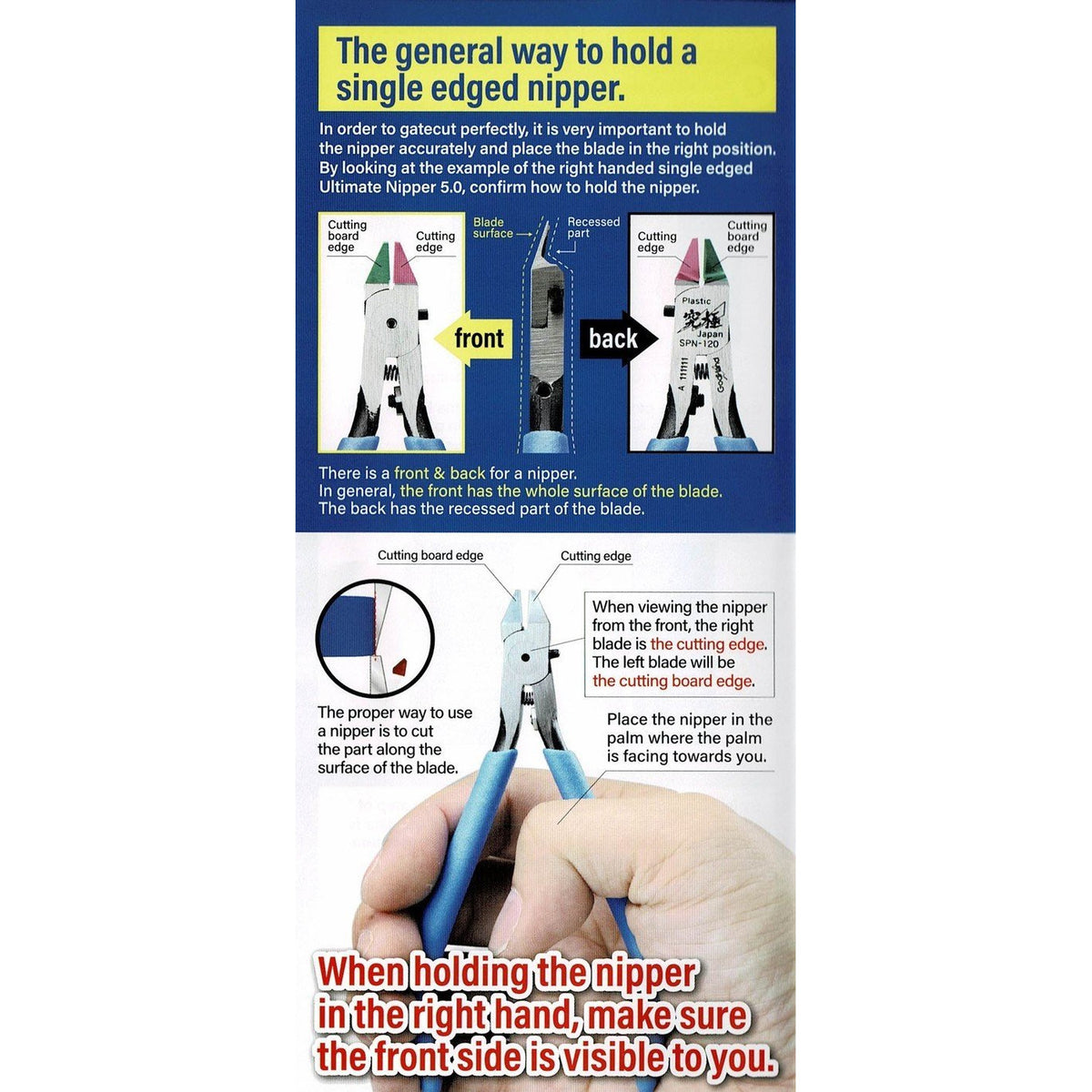

While both designs will easily remove parts from plastic kit runners or sprues – there is a fundamental difference in the user operation of each type. Double edged nippers work in the same way as side cutters or diagonal pliers, similarly to scissors they have a pair of blades which are brought together evenly to make the cut.

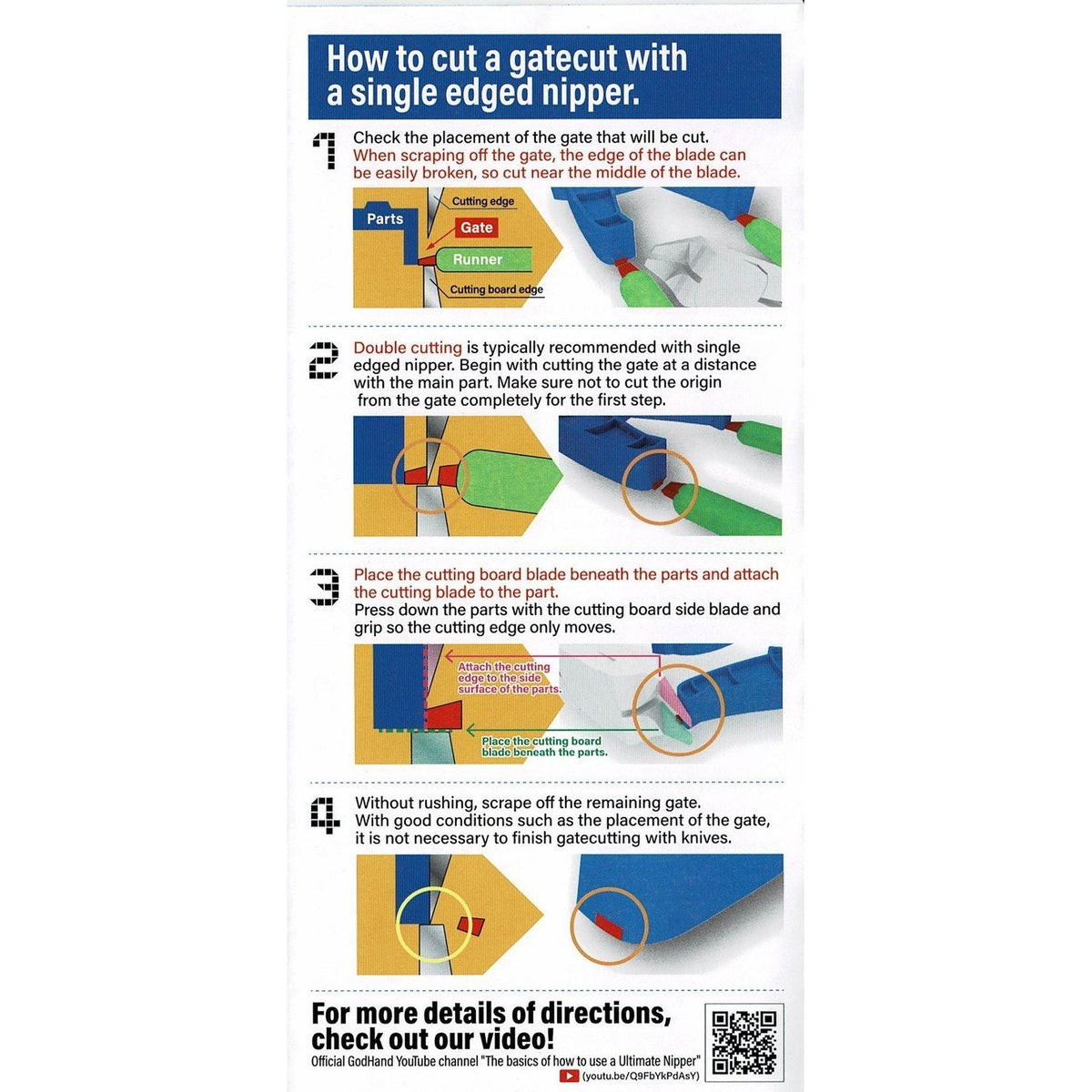

Single edged nippers differ from traditional side cutters in that they operate more like a guillotine than a pair of scissors. The sprue gate is placed against the lower “anvil” nipper blade and the upper “cutting” blade is brought downwards to provide the shearing action. This avoids pinching, common with double edged nippers, reducing plastic stress causing undesirable side effects such as whitening and providing the cleanest possible part removal.

While both designs will easily remove parts from plastic kit runners or sprues – there is a fundamental difference in the user operation of each type. Double edged nippers work in the same way as side cutters or diagonal pliers, similarly to scissors they have a pair of blades which are brought together evenly to make the cut.Single edged nippers differ from traditional side cutters in that they operate more like a guillotine than a pair of scissors. The sprue gate is placed against the lower “anvil” nipper blade and the upper “cutting” blade is brought downwards to provide the shearing action. This avoids pinching, common with double edged nippers, reducing plastic stress causing undesirable side effects such as whitening and providing the cleanest possible part removal.

| Title | Default |

|---|

Quick Shipping and Professional Packaging

Due to our long-term partnership in a long-standing partnership with UPS, FedEx, DHL and many other leading global carriers, we are able to offer an array of shipping options. Our warehouse staff are highly trained and will pack your products according to our precise and precise specifications. Your items will undergo a thorough inspection and be securely secured prior to being delivered. We ship to thousands clients each day across multiple countries. This is an indication of our dedication to being the biggest online retailer in the world. The warehouses are located in Europe as much as they are in the USA.

Note: Orders that include more than one item are assigned a processing time in accordance with the item.

Prior to shipment before shipping, we'll inspect thoroughly the items you've ordered. The majority of orders are shipped within 48 hrs. The time to deliver varies from 3-7 days.

Returns

We don't manage the stock in our warehouse and factory. Stocks are subject to change at any moment. You may not receive your order after the order has been made.

Our policy is for 30 days. If you have passed 30 days by since your purchase, unfortunately we can't offer you a refund or exchange.

The item cannot be used and in its original condition. It should also be in the original packaging.

Related products

RADIO CONTROL

RADIO CONTROL

(Clearance Item) HB RACING 5 Cell Main Chassis 2.5mm with Battery Tray (Cyclone) HB RACING

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

(Clearance Item) HB RACING 44mm Heavy Duty Universal Drive Shaft/Rear/Steel/2Pcs HB RACING