HWS 1/16 Saukopf (Topfblende) for Sturmgeschtz StuG III HEARNS WORKSHOP

$ 34,99 $ 20,99

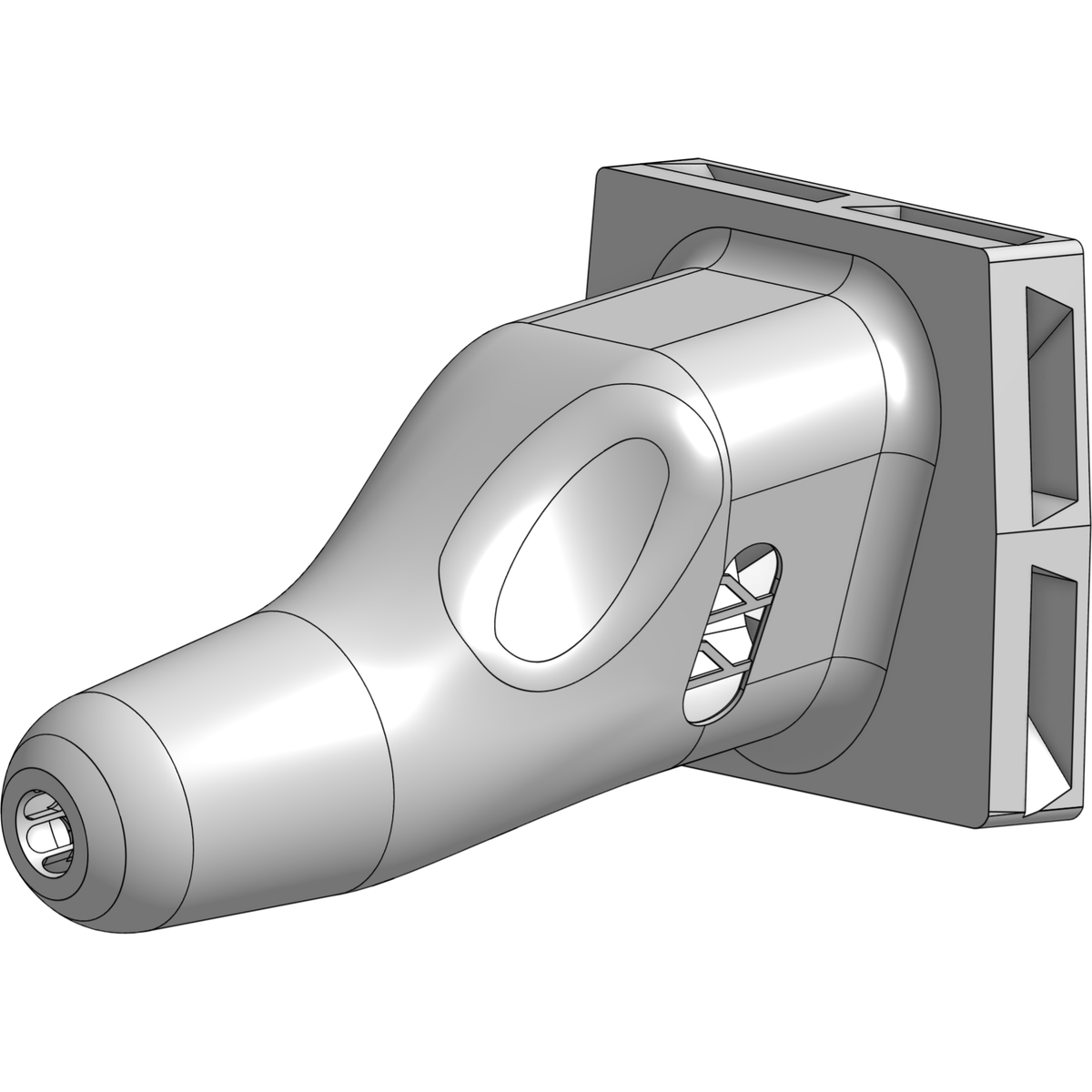

Hearns Workshop Muzzle Saukopf (Topfblende) for Sturmgeschutz

Stug III – 1pcs, 1 type with three swappable casting numbers

(HWS0110-16) for Late Production units.

The cast mantlet or ’Topfblende’ was introduced in November 1943 on the StuG III Ausf. G production, but StuG IIIs with the bolted “box” mantlet continued in production until the end of the war as production of the cast mantlet was insufficient to cover all of StuG production.

The Saukopf mantlet began to appear in November of 1943 but never completely replaced the welded mantlet which was seen until the end of the conflict simply because production of them could not keep pace with requirements. The official name for this new mantlet was ‘Topfblende’, but was commonly know as the ‘Saukopf’ by the crews, as it resembled a pig’s head or snout. It was used on the StuG III Ausf. G, StuG IV and StuH. from November 1943 to the end of the war.

For our requirements, it’s application is appropriate for any Alkett produced StuG III Ausf.G from October 1943 until April 1945.

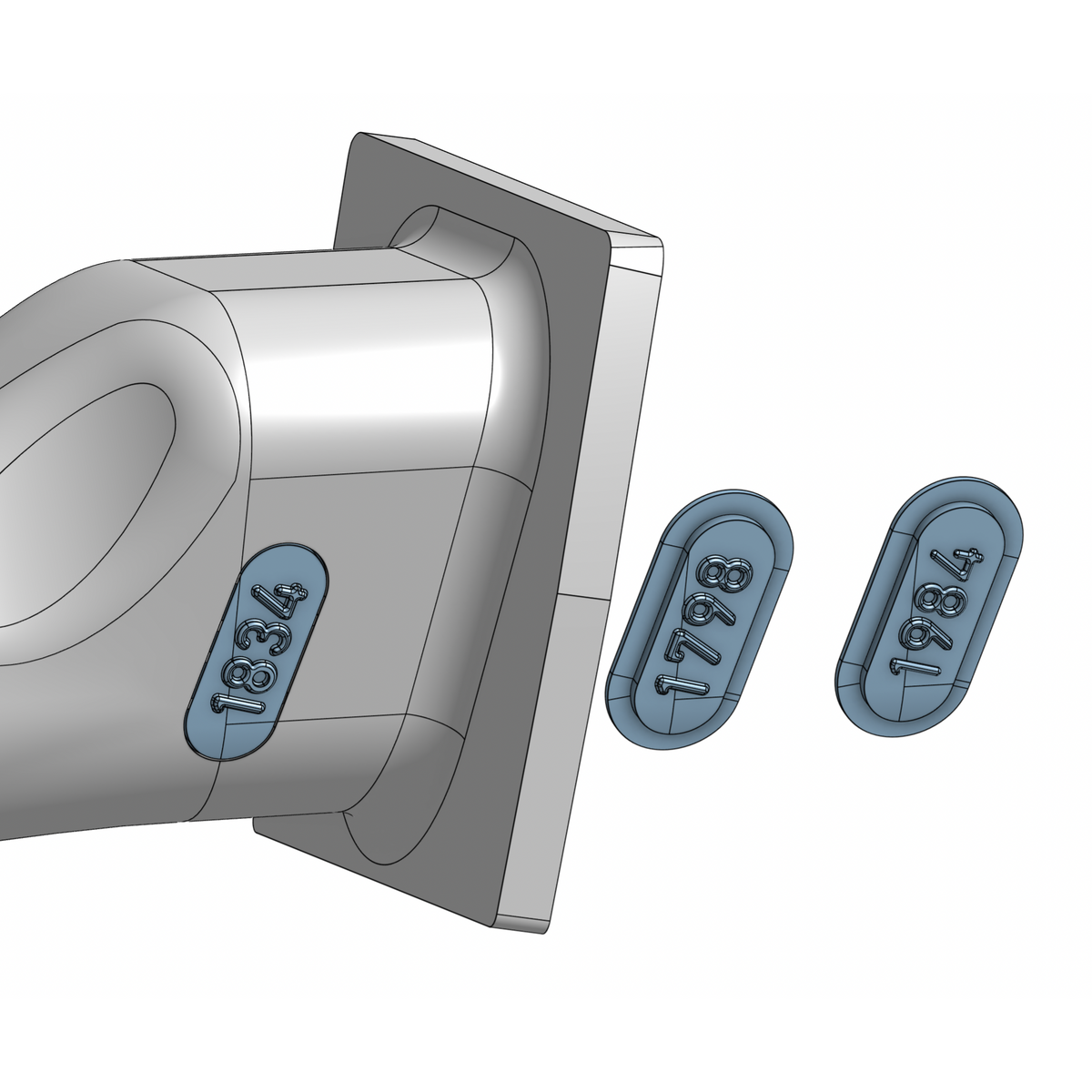

Your particular Saukopf comes with the unique feature of swappable casting numbers for a unique look. These can be superglued in and the gap filled with your putty of choice. After application of the casting number, add a texture to the Saukopf to blend in the casting number and give it a one-off look – just like the real thing!

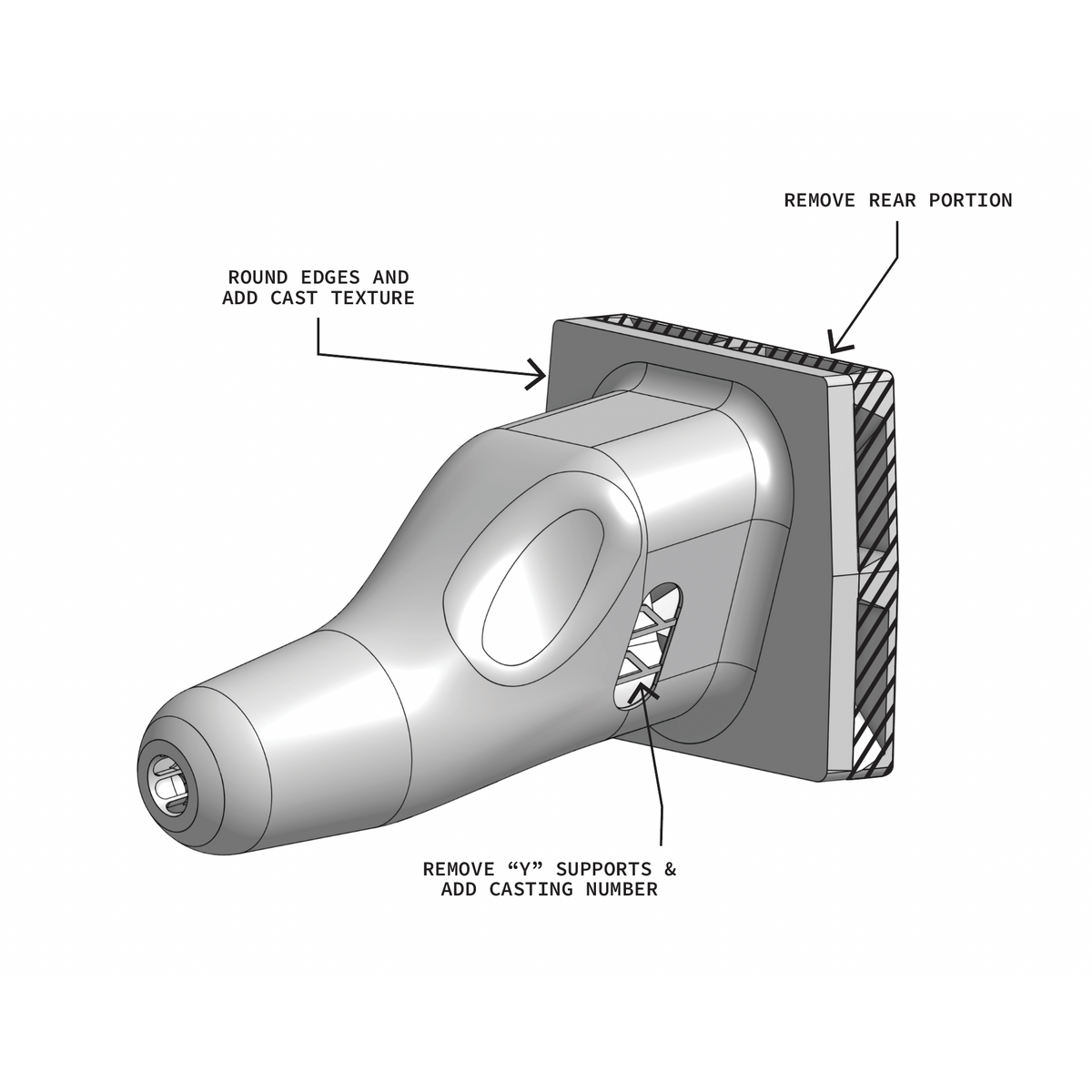

Each unit has a base to assist in the printing process which must be removed with a jewellers’ saw before assembly. Also to aid assembly, a small section of the gun (parts H2 and H3) must be removed. See illustrative image for more information.

PLEASE NOTE: The barrel hole is designed specifically to fit the 1/16 Das Werk Stug III Ausf.G machined aluminium barrel. Measure the barrel diameter on your kit and ream to suit.

DISCLAIMER – Parts are manufactured from a UV curing resin.

Cyanoacrylate(CA) or “Super Glue” recommended for bonding to rigid PS/ABS or other resin parts. UV curing resins can be an irritant. Always use the appropriate safety gear when handing or modifying. Parts are supplied still attached to the supports/raft. Care must be taken when removing supports. 3D printing IS NOT injection molding! Slight imperfections and the visible appearance of ‘layer lines’ in places is perfectly normal and not a defect. ‘Tough’ grade resin parts can damage fine bladed side cutters – use at own risk. For advanced modellers only.

Quick Shipping and Professional Packaging

Due to our long-term partnership in a long-standing partnership with UPS, FedEx, DHL and many other leading global carriers, we are able to offer an array of shipping options. Our warehouse staff are highly trained and will pack your products according to our precise and precise specifications. Your items will undergo a thorough inspection and be securely secured prior to being delivered. We ship to thousands clients each day across multiple countries. This is an indication of our dedication to being the biggest online retailer in the world. The warehouses are located in Europe as much as they are in the USA.

Note: Orders that include more than one item are assigned a processing time in accordance with the item.

Prior to shipment before shipping, we'll inspect thoroughly the items you've ordered. The majority of orders are shipped within 48 hrs. The time to deliver varies from 3-7 days.

Returns

We don't manage the stock in our warehouse and factory. Stocks are subject to change at any moment. You may not receive your order after the order has been made.

Our policy is for 30 days. If you have passed 30 days by since your purchase, unfortunately we can't offer you a refund or exchange.

The item cannot be used and in its original condition. It should also be in the original packaging.

Related products

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL

(Clearance Item) HB RACING 44mm Heavy Duty Universal Drive Shaft/Rear/Steel/2Pcs HB RACING

RADIO CONTROL

RADIO CONTROL

RADIO CONTROL